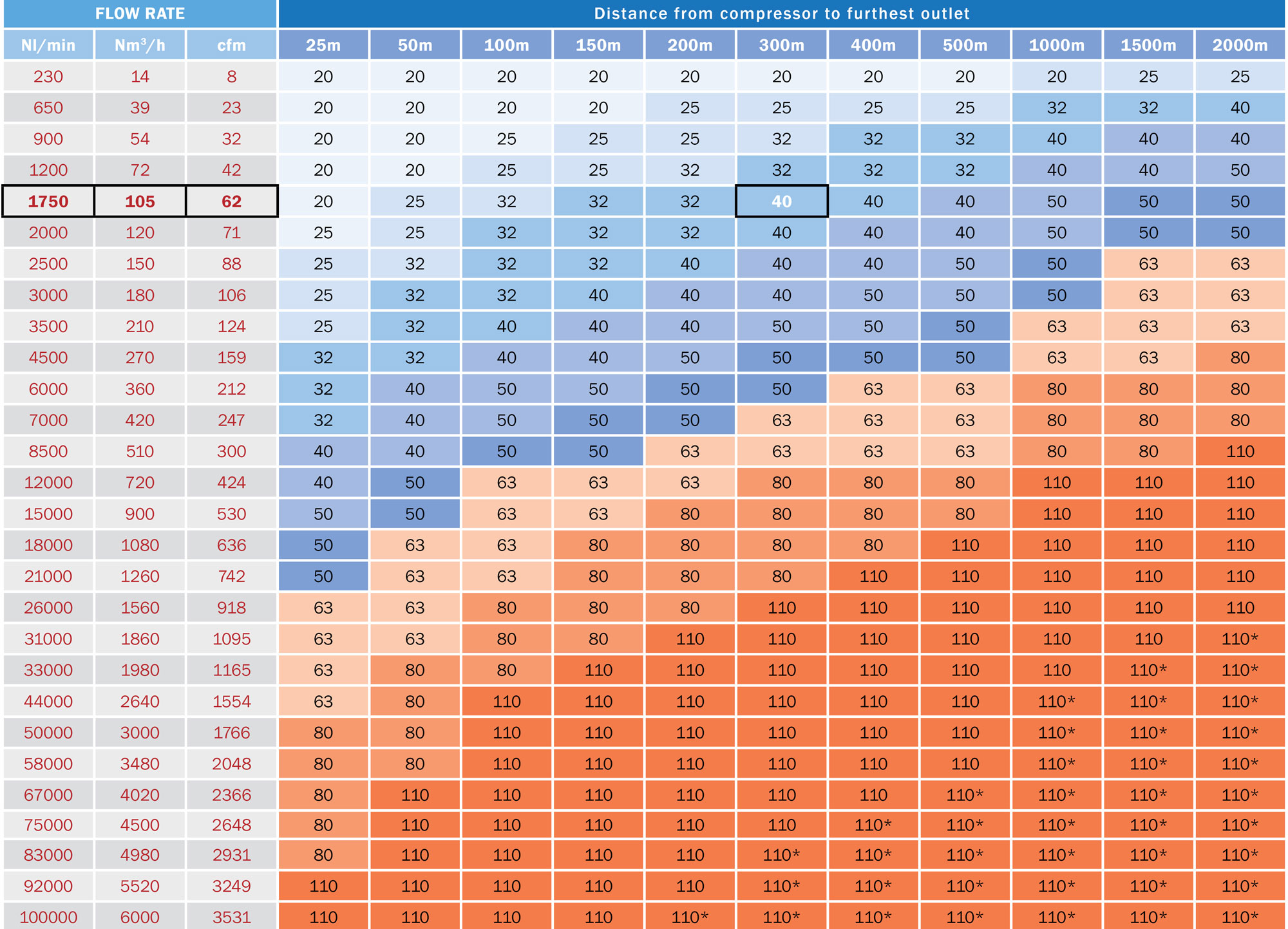

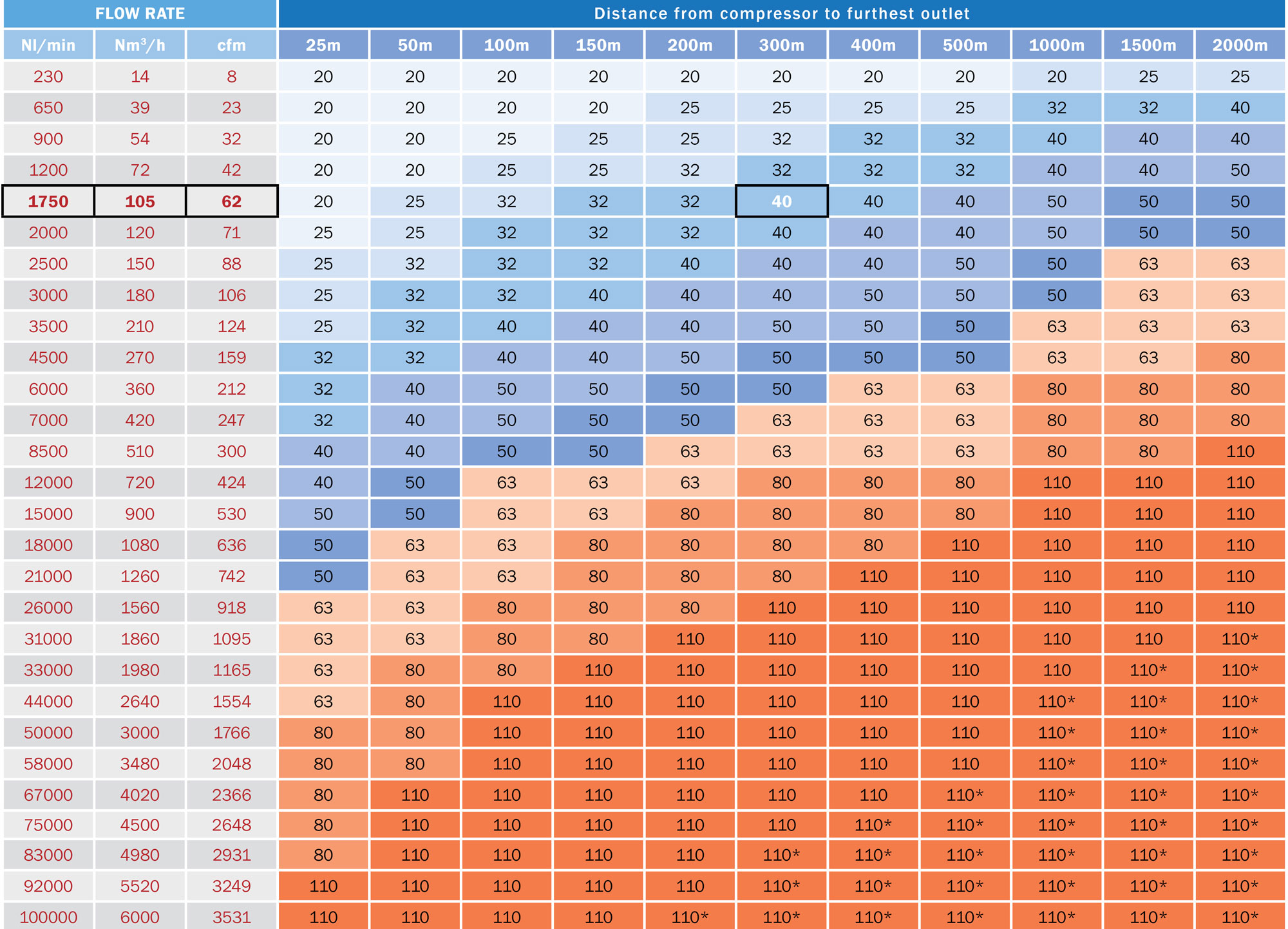

Infinity Pipe Systems Aluminium Compressed Air Pipe Sizing Chart allows you to determine the diameter (mm) of the compressed air pipe main line.

Here are the steps to determine the correct aluminium pipe sizing to suit your needs:

- Choose the flow rate of the air compressor in the red column.

- Choose the distance between the air compressor and the furthest dropper or outlet point in the blue column.

- Cross the lines of compressed air flow rate and the blue column of distance to identify the aluminium air pipe diameter.

Pressure 7 bar – Total pressure drop 4%

* Pressure drop is higher than 4%

Common Compressed Air Pipe Sizing Chart Questions

What happens if my pipe diameter is too small?

High velocity is caused from under sizing of compressed air pipe systems. The most overlooked area in aluminium compressed air piping layout and design is the velocity of the compressed fluid. Under-sizing the diameter of the compressed air pipe will increase the velocity.

What’s wrong with high velocity?

Fluid runs through the system faster, when it hits a valve or crossing tee, all the accumulated energy creates high turbulence and therefore significant back pressure. This back pressure in your compressed airline can have a very negative impact on your compressed air system’s performance and running costs.

High velocity (under sizing the pipe system) can be a significant cause of:

- Erratic pressure control

- Turbulence in the air pipe system

- A drop in pressure, and

- Extra power requirements at the compressor

Ready to take a look at Infinity Pipe Systems Aluminium Compressed Air Pipe?