What happens to your compressed air line in winter?

Cold weather brings with it a particular set of challenges for compressed air systems and a number of problems can occur when temperatures drop below 5˚C. Its is important to know how cold ambient temperatures affect your compressed air system.

What can happen if the ambient temperature is very low?

Condensation

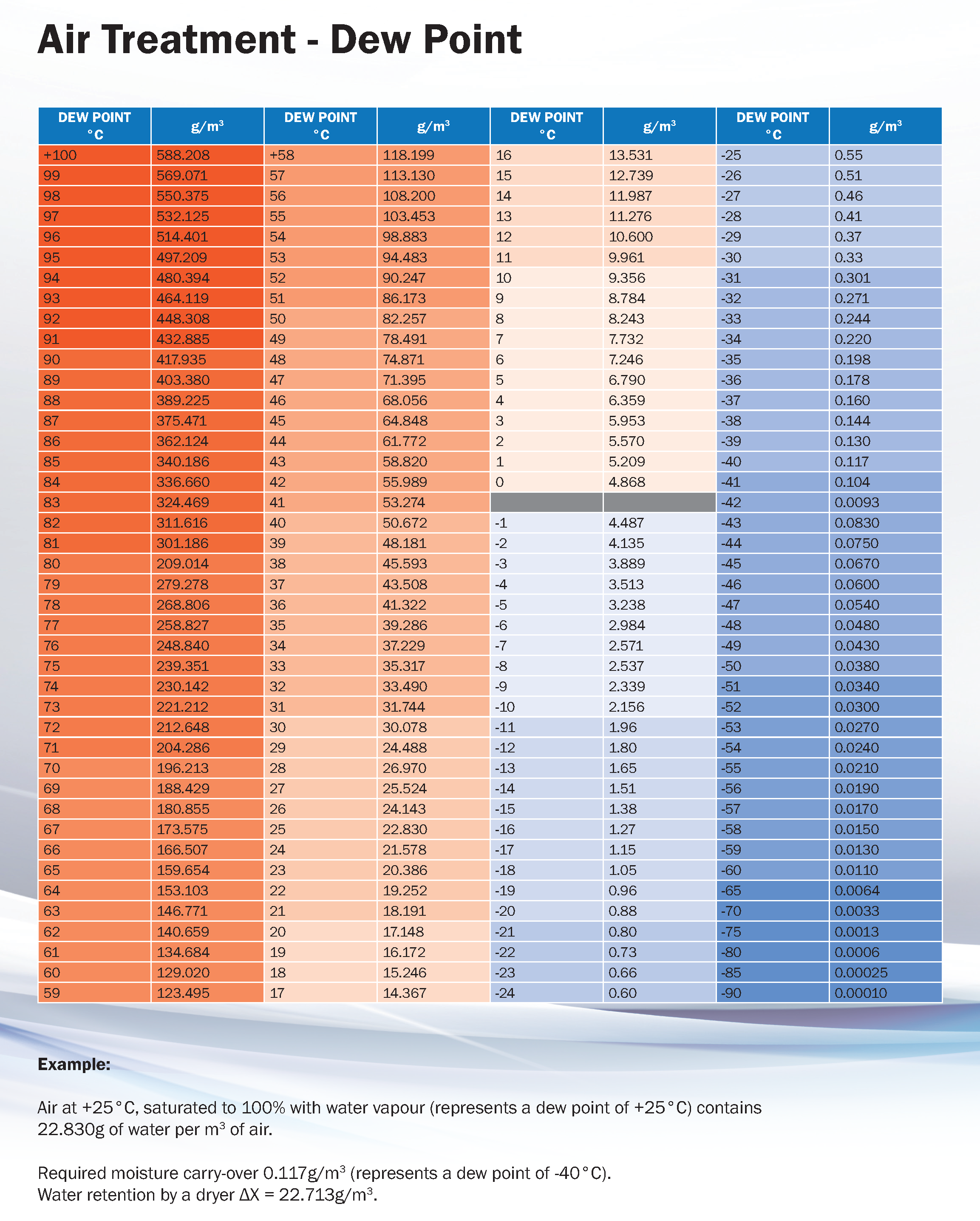

The chances of condensation are very high with low ambient temperatures. The moment water vapour in your compressed air system condensates (dewpoint) is related directly to the ambient temperature. Condensation in compressed air can cause big damage to piping, tools and other appliances. This can lead to breakdowns, air leakages and thus excessive costs.

Fluid in the oil

The operating temperature of the compressor stays low because of cold ambient air. This has negative impacts on the lubrication of your machine and may cause malfunction or breakdown.

Freezing

When temperatures are very low, compressed air lines, condensate drains and filters can freeze over. Even the aftercooler of your compressor can freeze and break down because the freezing cold hits the cooler directly via the cooling air vent. Be sure to prevent this by putting your cooling air vent to a winter-level.

Condensate in compressed air systems can cause the below;

- Inconsistent supply of dry air will cause production problems.

- Formation of rust and scale in the air line.

- Your air dryers and inline filtration products will not perform if they become overloaded with liquid contamination.

- Water can back up into the compressor and wreck the machinery.

- Moisture freezing at the point of exhaust and reducing tool efficiency.