Comparing two of the most popular grades of stainless

While the two most popular grades of stainless steel might seem identical at a glance, they hold important differences that can lead to substantial savings over the life of your project depending on your intended uses.

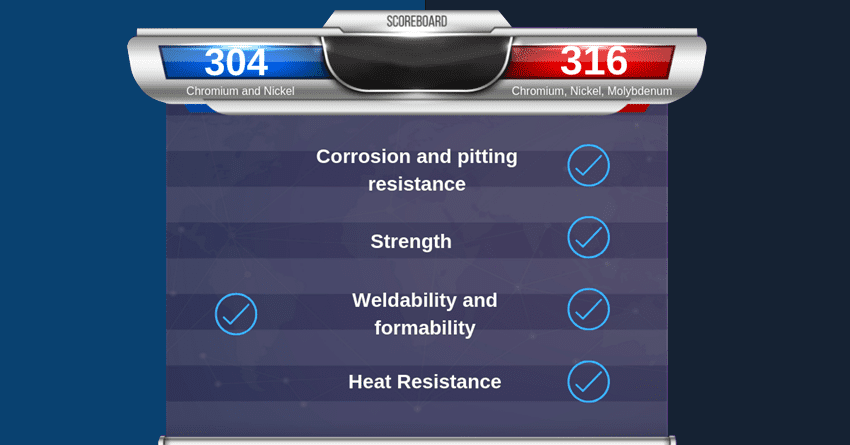

The two most common stainless steel grades are 304 and 316. The key difference is the addition of molybdenum, an alloy which drastically enhances corrosion resistance.

316 stainless steel contains molybdenum. 304 stainless steel does not.

What is 304 Stainless Steel and Where Is It Used?

Due to its superior corrosion resistance and value, 304 stainless steel is the most widely used type of stainless steel in the world. It is a highly heat-resistant grade, and offers good corrosion resistance to many chemical corrodents. It is commonly known as ‘kitchen grade’

Some of the more common applications for grade 304 steel are:

- Pots and pans

- Fasteners

- Electrical enclosures

- Kitchen equipment and appliances

What is 316 Stainless Steel and Where Is It Used?

In terms of commonality, 316 steel comes in second. 316 stainless steel is more optimal in environments that include a high amount of corrosive elements, the material will be placed underwater, or in applications that require greater strength and hardness.

Some of the more common applications for grade 316 steel are:

- Medical-surgical instruments

- Pharmaceutical

- Chemical processing

- Food & Beverage

- Marine environments

So 304 or 316 Grade?

The most important factor to consider is if you have an application with very powerful corrosives or one that relies on chlorides, then paying a premium for grade 316 stainless steel will result in a product that will last many times longer than grade 304 stainless.

However, for applications using milder acids or where salt exposure isn’t a concern, grade 304 stainless steel can work just as well.