Did you know aluminium piping was initially introduced in the late 1980s as a smarter alternative to plastic and steel pipe in compressed air systems?

Traditionally, engineers have specified a variety of piping materials for compressed air systems, including, but not limited to galvanised steel, stainless steel, copper, and even PVC.

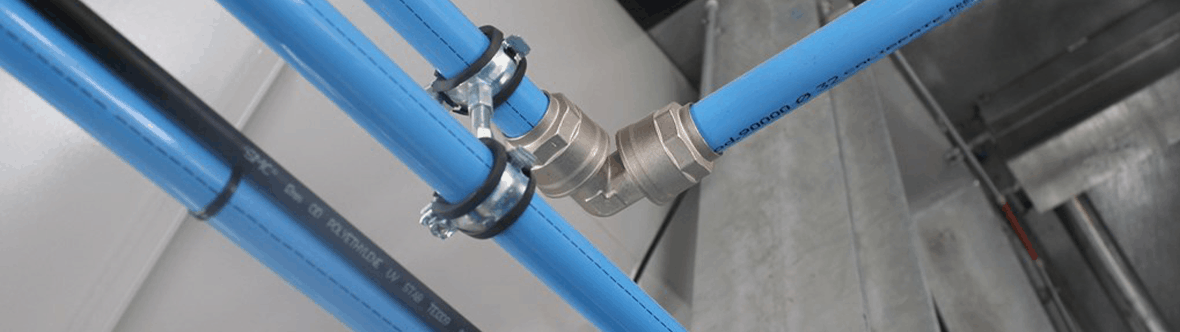

Many companies have made the switch to the industry standard for compressed air – Aluminium Piping. However, many of the benefits associated with an aluminium system are lost with the addition of plastic fittings.

Reduced costs and increased longevity are just two of the many advantages of using aluminium piping to install a compressed air system.

BENEFITS OF INFINITY PIPING SYSTEMS

- Up to 50% savings in labour, since the aluminium pipe is supplied ready for use

- Infinity pipe is lighter than steel or copper alternatives, reducing installation and modification costs

- Infinity piping doesn’t require threading, soldering or unique skill sets

- No special tools, or preparations besides cutting and deburring required

- A compressed air system built with Infinity piping is much cleaner than air delivered by a steel pipe system.

- Infinity pipe’s corrosion-resistant properties offer optimal airflow, reduced energy costs, and better air quality overall. \

Operating in the compressed air industry for over ten years, Infinity Pipe Systems can supply, design and build a full aluminium piping system based on maximum optimisation and safety.

We will work closely with you to create a customised compressed air plan that ensures reduced energy costs, minimal maintenance and allowance for future expansion.