From assembly lines to auto repair shops, compressed air powers nearly every corner of the automotive world. It’s the unseen force behind efficient production, precision tools, and quality finishes – keeping the industry moving, one application at a time.

Below, we explore how compressed air drives performance in automotive manufacturing, servicing, and beyond – and what to consider when designing a reliable system.

Read our guide: Design Considerations for Compressed Air Piping Systems

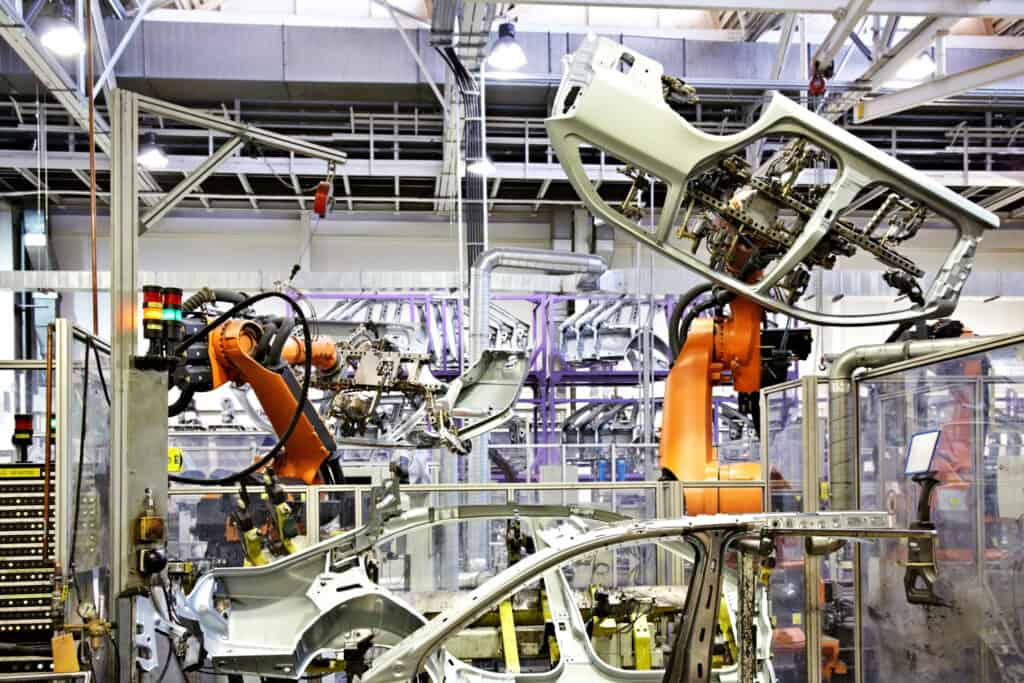

Air-Operated Robotics

Modern automotive manufacturing runs on automation – and automation runs on compressed air.

Robots use pneumatic actuation for clamping, lifting, and positioning in the press shop, as well as in painting, welding, and assembly processes. Pneumatics deliver clean, consistent force and rapid response, making them ideal for repetitive high-speed production environments.

Air Tools

Pneumatic tools are the backbone of vehicle assembly and maintenance.

From air-powered wrenches and ratchets to saws, grinders, and drills, these tools offer the power, precision, and reliability needed for high-throughput environments – without the heat and vibration fatigue of electric alternatives. They’re commonly used for fastening, cutting, grinding, and other fabrication or repair tasks where efficiency and consistency matter.

Paint Shop Operations

In the paint booth, compressed air is the painter’s most valuable asset.

Low-pressure compressed air is used to atomise and propel paint through spray guns for even, high-quality coatings. It also keeps paint baths agitated to prevent clumping and ensure colour consistency. The quality of the air supply directly impacts the quality of the finish – any contamination in the air can compromise adhesion, gloss, and long-term corrosion protection.

Tyre Fitting and Inflation

From the factory floor to the local workshop, compressed air keeps wheels turning.

Air tools remove and refit wheel nuts, while the same system supplies the air to inflate tyres to precise pressures – a process that depends on consistent, dry, and contaminant-free air to maintain safety and performance.

What to Consider When Using Compressed Air

Contaminant-Free Air

Air purity is critical – especially in finishing and assembly applications where even microscopic contamination can cause costly defects.

Common issues include:

-

Solid particles (like rust or scale) that clog spray nozzles and damage tools.

-

Oil aerosols that cause paint flaking, beading, or poor adhesion.

-

Moisture that blocks air passages, promotes corrosion, and compromises finish quality.

Moisture can also accumulate in low points of pipework or in receivers, releasing unexpectedly during use – often through spray guns or tools – resulting in rework or scrap.

Air Preparation and Filtration

Protecting equipment and ensuring system reliability starts with proper air preparation.

An effective FRL unit (Filter, Regulator, Lubricator) ensures that air is clean, pressure is stable, and downstream tools receive the right level of lubrication. This reduces wear, extends tool life, and maintains consistent performance.

For paint and finishing applications, adding air dryers and coalescing filters further removes moisture and fine contaminants – helping maintain finish integrity and preventing downstream damage.

The Bottom Line

Compressed air is indispensable in the automotive industry – but like any system, its performance depends on how well it’s designed, filtered, and maintained. From production robots to spray guns and tyre inflators, every process benefits from clean, consistent, and well-regulated air.

Infinity Pipe Systems delivers engineered compressed air solutions that optimise flow, reduce pressure drop, and protect equipment – so your system performs as reliably as the vehicles it helps build.

Explore our range of compressed air piping solutions including filtration, couplings and hose reels.

Build your next system with confidence – choose Infinity Pipe Systems for clean, reliable, and high-performance compressed air delivery.