How to Work Safely with Compressed Air Lines

In recognition of National Safe Work Month this October, Infinity Pipe Systems has compiled a list of handy hints and important safety precautions to consider when working with compressed air lines.

- Only OEM fittings should be used on air lines.

- Air lines should be inspected frequently with any defective equipment repaired or replaced immediately.

- Compressed air lines should be identified as to maximum working pressures (psi), by tagging or marking pipeline outlets.

- All pipes, hoses, and fittings must have a rating consistent with the maximum pressure of the compressor.

- Operators should avoid bending or kinking air hoses.

- Air hoses should not be placed where they will create tripping hazards.

- Air hoses should be kept free of grease and oil to reduce the possibility of deterioration.

- Hoses should be checked to make sure they are properly connected to pipe outlets before use.

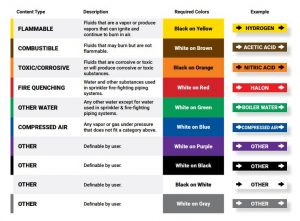

Marking pipes can help make the workplace safer and more efficient. When pipes are clearly

labelled, fewer accidents involving injuries and damage to property occur. Make sure workers can tell at a glance which pipes carry compressed air and which carry other gases or other liquids under pressure.

Because many companies use pipelines to carry many different substances, staff should be strongly aware of the Content Identification requirements of AS 1345-1995.

Our Infinity Project Management Team and Designers are committed to complying to Australian Standards and Good Work Design. With support documentation and proven competency, our staff is qualified to perform consultation, design, installation and maintenance support for any airline, Australia wide.