- Home

- Shop

- Compressed Air Filtration

- Industrial Filtration

- Industrial Coalescing Filter

Industrial Coalescing Filter

Industrial Coalescing Filter

Code Number – IN-F-130

- Removes liquid, oil and water from a compressed air stream

- Filtration rating: 0.01µm

- Oil content: 1ppm

- Maximum pressure: 232 psi

- Description

- Technical

- Related Literature

- Contact Form

Product Description

The Infinity industrial coalescing filter is made of high quality aluminium alloy and carbon steel.

Featuring a compact design to reduce space for maintenance, its surface is coated with epoxy resin powders so as to improve its durability and resistance to corrosion.

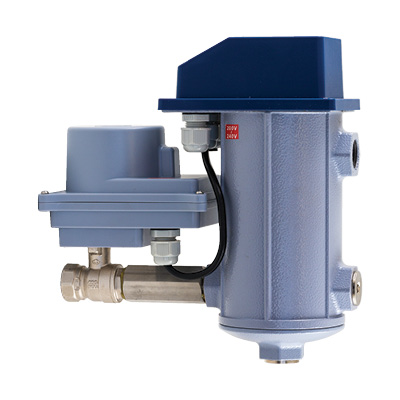

The coalescing filter features a high quality industrial float drain with ball valve for easy condensate removal, and a threaded connection is used as both an inlet and outlet.

The filter housing is marked with direction of air flow for ease of use, and the auto drain is serviceable without shutting off the air supply.

| CODE | DESCRIPTION | MICRONS | FLOW RATE CFM | MAX PRESSURE PSI | MAX TEMP | CONNECTION SIZE |

| IN-F15C-130 | Coalescing Filters 1/2″ | 0.01 | 35 | 232 | 65°C | 1/2” |

| IN-F20C-130 | Coalescing Filters 3/4″ | 0.01 | 70 | 232 | 65°C | 3/4” |

| IN-F25C-130 | Coalescing Filters 1″ | 0.01 | 105 | 232 | 65°C | 1” |

| IN-F40C-130 | Coalescing Filters 1 1/2″ | 0.01 | 210 | 232 | 65°C | 1 1/2” |

| IN-F50C-130 | Coalescing Filters 2” | 0.01 | 630 | 232 | 65°C | 2” |

| IN-F63C-130 | Coalescing Filters 2 1/2” | 0.01 | 840 | 232 | 65°C | 2 1/2” |

The main function of the coalescing filter is to trap and subsequently remove liquid, oil and water from a compressed air stream.

The separation of aerosol and solid contaminants from air is primarily dictated by gravity. Larger contaminants settle out of the air stream fairly quickly, however extremely small aerosol particles remain suspended, particularly in flowing air. The coalescing filter combines these aerosols into even larger droplets as they pass through the filter element’s fibre matrix, eventually becoming large enough to be susceptible to the force of gravity and be drained away.

The coalescing filter can be seen as a multifunctional filtration solution, due to its ability to filter particulates just as effectively as it can coalesce aerosols and droplets. If you have an application that requires both types of filtration, a coalescing filter is ideal.

To select the correct size of filter for a particular application, choose on the basis of air flow and system pressure, rather than pipe size. Select a filter large enough to ensure that the air exits the filter at a low velocity and does not carry over coalesced liquid.

Coalescing filters are ideal for use after air has flowed through the compressed air dryer, acting as an excellent condensate removal. They are best used with an Infinity pre-filter.

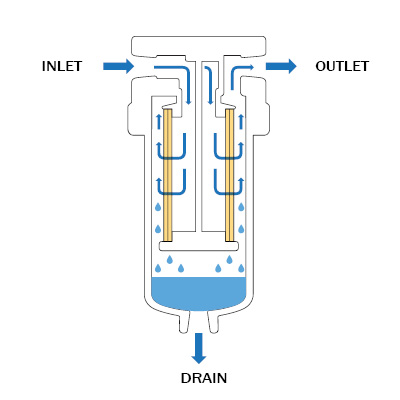

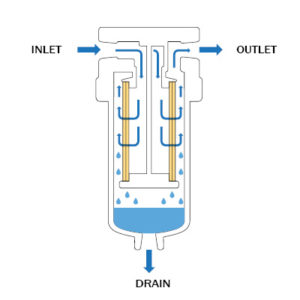

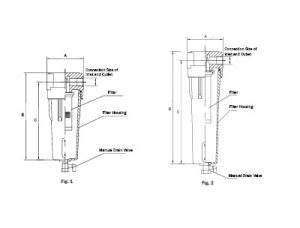

The diagram below shows the coalescing process.

Air enters the housing and flows through the filter media, passing from the inside element surface to the outside. Coalesced liquid collects in the bowl where it is drained and clean air exits the housing through the outlet port.

| CODE | FIG | A | B | C | CONNECTION SIZE |

| IN-F15C-130 | 1 | 104 +/-0.8 | 243 +/-1.2 | 217 +/-1.2 | 1/2” |

| IN-F20C-130 | 1 | 104 +/-0.8 | 313 +/-1.2 | 287 +/-1.2 | 3/4” |

| IN-F25C-130 | 1 | 104 +/-0.8 | 313 +/-1.2 | 287 +/-1.2 | 1” |

| IN-F40C-130 | 2 | 138 +/-0.8 | 624 +/-1.2 | 624 +/-1.2 | 1 1/2” |

| IN-F50C-130 | 2 | 148 +/-0.8 | 685 +/-1.2 | 639 +/-1.2 | 2” |

| IN-F63C-130 | 2 | 150 +/-0.8 | 850 +/-1.2 | 800 +/-1.2 | 2 1/2” |

Related Literature