When it comes to compressed air, performance starts long before the compressor. A well-designed piping system determines how efficiently air is delivered throughout your facility, influencing energy use, equipment lifespan, and overall reliability.

Designing an efficient compressed air piping system requires balancing flow performance, pressure stability, material selection, and long-term maintainability.

This guide outlines seven key design considerations based on best practice principles and engineering standards, with examples from the Infinity Pipe Systems range to illustrate material and system design factors relevant to Australian facilities.

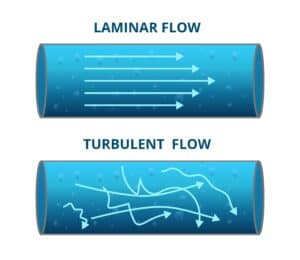

1. Flow Efficiency and Pressure Drop

A piping network must be sized to maintain adequate flow and pressure across all outlets, with minimal loss between the compressor and end use. Pressure drop is primarily influenced by pipe diameter, internal surface roughness, system layout, and fittings design.

Key principles:

- Use smooth, clean internal bores to promote laminar flow.

- Minimise sharp bends, restrictions, and long unsupported runs.

- Size the main line for current and future demand – our Aluminium Compressed Air Pipe Sizing Chart can help with this.

Infinity’s aluminium and stainless steel systems use precision-machined fittings and smooth internal surfaces to reduce turbulence. The thinner wall construction of aluminium provides a larger internal diameter than steel or plastic, resulting in lower frictional losses and higher available flow for a given pipe size.

2. Material Selection and Corrosion Resistance

Material choice affects not only performance but also air quality and maintenance intervals. Moisture, temperature variations, and contaminants can all accelerate corrosion, or deformation – such as sagging or bowing – in compressed air lines.

Selection considerations:

- Aluminium and stainless steel offer superior resistance to corrosion compared to galvanised or black steel.

- Internal coatings or treatments extend service life and prevent contamination.

- For outdoor or high-moisture environments, 316, or 316L grade stainless steel provides the best durability.

Infinity aluminium piping is chemically treated with a fluorine-zirconium coating that forms a protective barrier on the inner surface. For demanding conditions or high-pressure systems (up to 40 bar), Infinity Stainless provides a 316L-grade alternative tested to international pressure and corrosion standards.

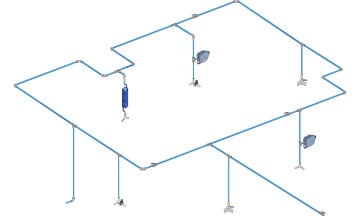

3. System Layout and Scalability

A well-planned layout ensures even air distribution and allows for future expansion – without major rework – as your facility grows

Modular systems simplify layout changes. The ability to add new branches or drops without welding or threading is beneficial in growing facilities or where production downtime must be minimised.

Lightweight options, such as aluminium, makes installation or modifications faster and safer, even at height.

Best practices:

- Use a closed-loop (ring main) design to balance pressure and flow across outlets.

- Minimising long runs, sharp bends, and dead-end branches.

- Incorporate isolation valves and drain points for maintenance.

- Design with clear access for inspection, maintenance and expansion.

Infinity’s modular piping systems are well-suited to facilities that evolve over time, allowing new outlets or extensions to be added with minimal disruption.

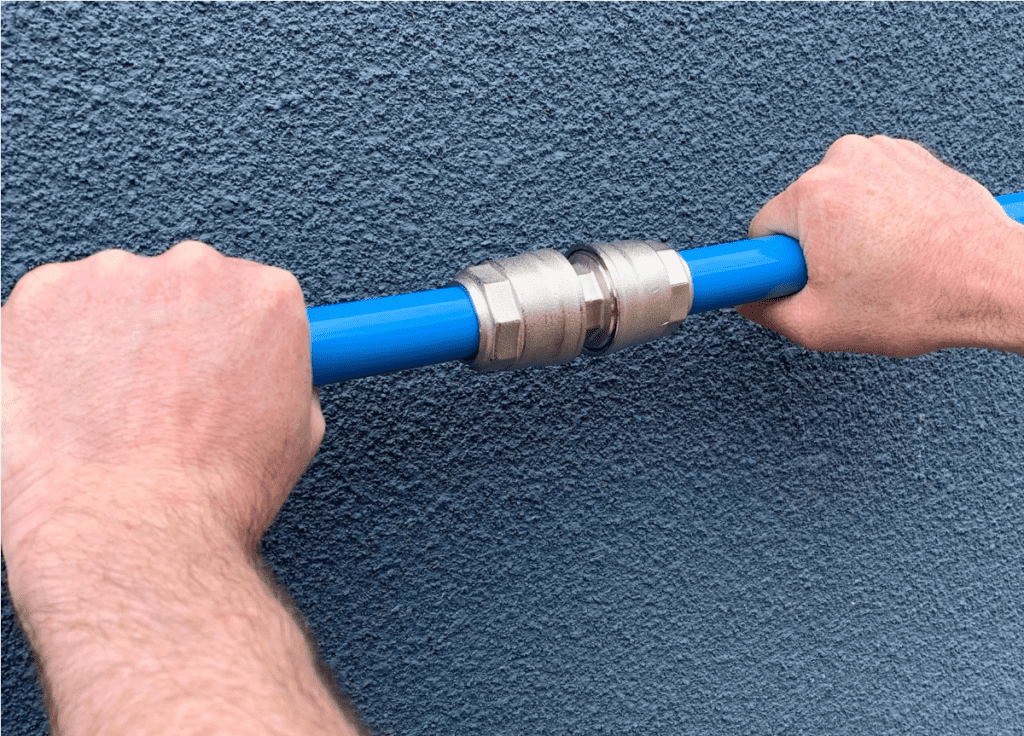

4. Leak Prevention and Joint Integrity

Even a small air leak can significantly increase running costs.

Leaks are a major source of energy waste. A 3mm opening at 700 kPa can leak more than 10 L/s of air – equivalent to several thousand dollars per year in lost energy*.

Design for integrity:

- Specify fittings that maintain sealing integrity under vibration and temperature cycling.

- Use mechanical compression or O-ring seals rather than thread sealant where possible.

- Pressure-test the system after installation and during scheduled maintenance.

Infinity fittings use precision O-ring seals and mechanical connections to achieve repeatable, leak-free performance. Systems should be inspected periodically using ultrasonic leak detection or pressure decay testing.

5. Standards, Safety, and Documentation

Compressed air systems in Australia are governed by AS4041-Pressure Piping and related workplace safety codes. Compliance ensures both safety and reliability.

Designers should confirm:

- Compliance to relevant Standards.

- The system’s pressure rating is suitable for the intended operating range.

- Documentation includes test data, material certificates, and installation guides.

Infinity Pipe Systems are AS4041-compliant and tested to international standards for pressure, temperature, and corrosion resistance. Drawings and BIM files are available to support engineering and construction.

Infinity Stainless range complies with Australian Standards and is WaterMark Certified.

6. Installation Efficiency and Lifecycle Cost

Installation time, maintenance access, and long-term performance all affect lifecycle cost. Lightweight and modular materials reduce labour effort, improve safety, and minimise downtime.

Technical considerations:

- Use materials that can be installed without welding or cutting oils.

- Avoid mixed-metal connections that may cause galvanic corrosion.

- Support pipework adequately to limit stress and vibration.

Infinity’s aluminium and stainless-steel systems can be installed with hand tools, eliminating hot-work permits and reducing installation risk.

Lightweight materials simplify handling and reduce structural support requirements. Combined with corrosion resistance and consistent performance, this results in a lower total cost of ownership.

7. Visual Standards, Identification and Maintenance

Consistent identification of services is critical for safety and maintenance.

Compressed air should be clearly marked according to AS 1345-Identification of the Contents of Pipes, Conduits and Ducts.

Infinity’s blue aluminium pipe complies with this standard and features a UV-stable, scratch-resistant coating that maintains visibility and a professional appearance in industrial environments.

In Summary

Designing a compressed air system involves more than connecting pipes. It’s about creating a network that delivers reliable performance, maintains efficiency, and supports long-term operational goals.

Infinity Pipe Systems provides the materials and engineering support to achieve that balance, helping consultants, installers, and facility managers design systems that perform as well in practice as they do on paper.

Ready to get started?

Our technical team can assist with system design, flow analysis, and material selection to suit your site conditions.

Infinity Pipe Systems supplies high-performing aluminium and stainless steel compressed air piping systems across Australia, with local support teams in WA, QLD, VIC and NSW and a trusted installer network nationwide.

Reach out to our team via phone or email to discuss your next project, or click the link below to send an enquiry.

Industry Sources

* Leak rate data adapted from the U.S. Department of Energy (2003), Atlas Copco Compressed Air Manual (2022), and the Compressed Air Association of Australia (2021). A 3 mm orifice at 700 kPa may lose approximately 10–14 L/s of air, equating to several thousand dollars per year in energy waste depending on compressor efficiency and operating hours.