- Home

- Shop

- Aluminium & Stainless Pipe & Fittings

- Infinity Pipe & Fittings (20mm-63mm)

- Aluminium Air Pipe 20mm – 168mm

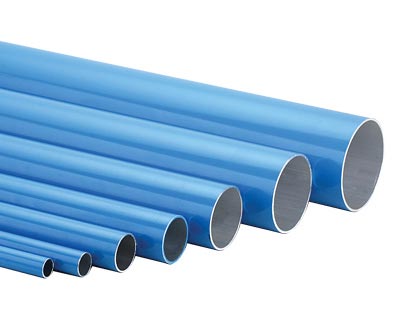

Aluminium Air Pipe 20mm – 168mm

Aluminium Air Pipe

Code Number – 900006

- Architectural grade seamless aluminium pipe, approved for pressures up to 16 bar

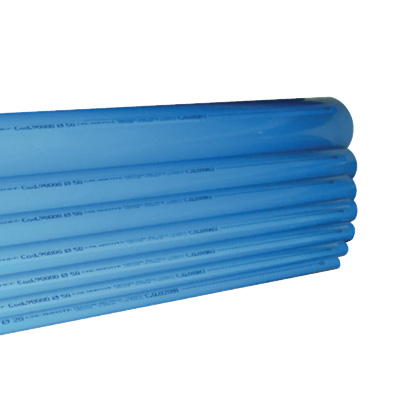

- Blue colouring for compressed air piping as per Australian standards

- Light-weight tubing

- Internal and external corrosion free coating

- Complies with Australian and European safety standards

- Includes High Flow Series (63mm – 168mm) for long ring main installations in large factories

SKU: 900006

Categories: Infinity Pipe & Fittings (20mm-63mm), Infinity Pipe & Fittings (80mm-168mm)

- Description

- Technical

- Related Literature

- Contact Form

Description

Product Description

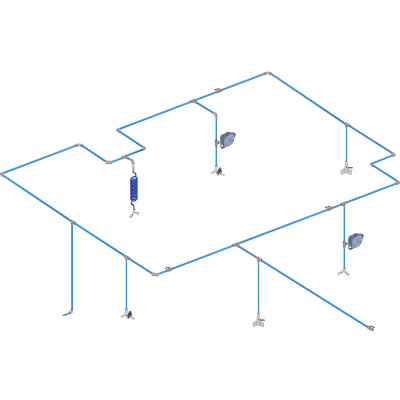

Aluminium Air Pipe – High performance aluminium piping system that is especially designed for air, indicated with blue colour, as per Australian standards. The non–corrosive extruded aluminium provides structural strength and delivers contaminate-free fluid in a leak free piping system.

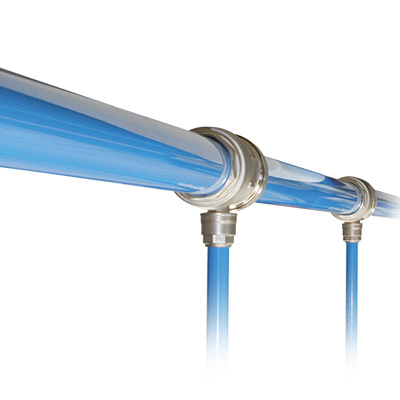

The smooth bore of Infinity piping prevents high pressure losses and allows for higher flow rates and performance than that of other systems.

High Flow Range – Specifically designed for long ring main installations in large factories, the high flow series feature a cast aluminium construction, offering the same benefits as the smaller range: easy push-fit installation, minimal leakage and laminar fluid flow. Available in 63mm-168mm diameters.

| Code | Description | Max Flow Rate (cfm) (25m, @7bar) |

| 900006 20 | Aluminium Pipe 20mm x 6m | 62 |

| 900006 25 | Aluminium Pipe 25mm x 6m | 124 |

| 900006 32 | Aluminium Pipe 32mm x 6m | 247 |

| 900006 40 | Aluminium Pipe 40mm x 6m | 424 |

| 900006 50 | Aluminium Pipe 50mm x 6m | 742 |

| 900006 63 | Aluminium Pipe 63mm x 6m | 1554 |

| 900006 80 | Aluminium Pipe 80mm X 6m | 2931 |

| 900006 110 | Aluminium Pipe 110mm X 6m | 3531 |

| 900006 168 | Aluminium Pipe 168mm X 6m |

Technical

| Max Pressure | 16 Bar |

| Working Temperature Range | -20 °C to 80 °C (Fire tested in accordance with UNI EN 13501-1:2005) |

| Uv Effect | NONE |

| Extruded Aluminium | UNI 9006/1 Al Mg 0.5 Si 0.4 Fe 0.2 |

| Chemical Composition | Si: 0.3 ÷ 0.6 - Mg: 0.35 ÷ 0.6 - Fe: 0.10 ÷ 0.30 |

| Designations Uni En 573 - 3 | EN AW 6060 |

| Heat Treatment / Melting Point | DRAINED “16” / 600°C |

| Surface Treatment | Electrostatic painting |

| Specific Weight / Resistance | 2.70 Kg/dm3 / 3.25 μΩ cm |

| Thermal Conductivity | 1.75 W/(cm °K) |

| Expansion Coefficient | 0.024mm/(m °C) |

| Specific Heat At 100°C | 0.92 J/(g °K) |

| Bearing Tensile Stress | 205 N/mm2 |

| Coefficient Of Elasticity | 66000 N/mm2 |

| Proportionality Deviation Load | 165 N/mm2 |

| Brinel Hardness | 60 ÷ 70 HB |

| Chemical Treatment | Fluorine-Zirconium - prevents corrosion from acid condensing water & sticks like a film on the internal surface of the tube. |

| External Coating / Internal Coating | Epoxypolyester Powder / Chemically treated with fluorine-zirconium. |

| Quality Features | UV resistant and fire tested in accordance with UNI EN 13501-1:2005 |

Related Literature

Contact Form