- Home

- Shop

- Aluminium & Stainless Pipe & Fittings

- Infinity Pipe & Fittings (20mm-63mm)

- Aluminium Vacuum Pipe 20mm – 168mm

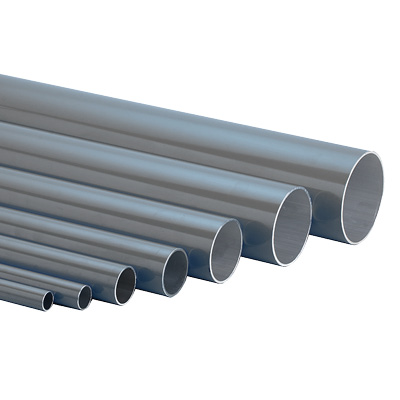

Aluminium Vacuum Pipe 20mm – 168mm

Aluminium Vacuum Pipe

Code Number – 900006GR

- Architectural grade seamless aluminium pipe, approved for pressures up to 16 bar

- Grey colouring for Vacuum piping as per Australian standards

- Light-weight tubing

- Internal and external corrosion free coating

- Complies with Australian and European safety standards

- Includes High Flow Series (63mm – 110mm) for long ring main installations in large factories

- Description

- Technical

- Related Literature

- Contact Form

Product Description

Infinity Vacuum Pipe is a high performance aluminum piping system that is easy to install and simple to extend or modify.

The non–corrosive extruded aluminum provides structural strength and delivers contaminate-free vacuum in a leak free piping system. The smooth bore of Infinity piping prevents high pressure losses and allows for higher flow rates and performance than that of other systems. No vacuum leakage ensures minimum running costs

High Flow Range – Specifically designed for long ring main installations in large factories, the high flow series feature a cast aluminium construction, offering the same benefits as the smaller range: easy push-fit installation, minimal leakage and laminar fluid flow. Available in 63mm-168mm diameters.

| Code | Description | Max Flow Rate (cfm) (25m, @7bar) |

| 900006GR 20 | Aluminium Pipe 20mm x 6m | 62 |

| 900006GR 25 | Aluminium Pipe 25mm x 6m | 124 |

| 900006GR 32 | Aluminium Pipe 32mm x 6m | 247 |

| 900006GR 40 | Aluminium Pipe 40mm x 6m | 424 |

| 900006GR 50 | Aluminium Pipe 50mm x 6m | 742 |

| 900006GR 63 | Aluminium Pipe 63mm x 6m | 1554 |

| 900006GR 80 | Aluminium Pipe 80mm X 6m | 2931 |

| 900006GR 110 | Aluminium Pipe 110mm X 6m | 3531 |

| 900006GR 168 | Aluminium Pipe 168mm X 6m |

| Max Pressure | 16 Bar |

| Working Temperature Range | -20 °C to 80 °C (Fire tested in accordance with UNI EN 13501-1:2005) |

| Uv Effect | NONE |

| Extruded Aluminium | UNI 9006/1 Al Mg 0.5 Si 0.4 Fe 0.2 |

| Chemical Composition | Si: 0.3 ÷ 0.6 - Mg: 0.35 ÷ 0.6 - Fe: 0.10 ÷ 0.30 |

| Designations Uni En 573 - 3 | EN AW 6060 |

| Heat Treatment / Melting Point | DRAINED “16” / 600°C |

| Surface Treatment | Electrostatic painting |

| Specific Weight / Resistance | 2.70 Kg/dm3 / 3.25 μΩ cm |

| Thermal Conductivity | 1.75 W/(cm °K) |

| Expansion Coefficient | 0.024mm/(m °C) |

| Specific Heat At 100°C | 0.92 J/(g °K) |

| Bearing Tensile Stress | 205 N/mm2 |

| Coefficient Of Elasticity | 66000 N/mm2 |

| Proportionality Deviation Load | 165 N/mm2 |

| Brinel Hardness | 60 ÷ 70 HB |

| Chemical Treatment | Fluorine-Zirconium - prevents corrosion from acid condensing water & sticks like a film on the internal surface of the tube. |

| External Coating / Internal Coating | Epoxypolyester Powder / Chemically treated with fluorine-zirconium. |

| Quality Features | UV resistant and fire tested in accordance with UNI EN 13501-1:2005 |