- Home

- Shop

- Compressed Air Filtration

- Industrial Filtration

- Industrial Absorption Filter

Industrial Absorption Filter

Industrial Absorption Filter

Code Number – IN-F-150

- Absorb smells, odours and taste from compressed air, making it suitable and comfortable for breathing

- Filtration rating: 0.01µm

- Oil content: 0.003ppm

- Maximum pressure: 232 psi

- Description

- Technical

- Related Literature

- Contact Form

Product Description

Activated absorption filters offer the final stage of filtration. The activated carbon removes smells and odours from the system, particularly important in breathing air systems. Combined with an Infinity pre-filter and coalescing filter, this filter set will offer air to a quality of 0.003ppm.

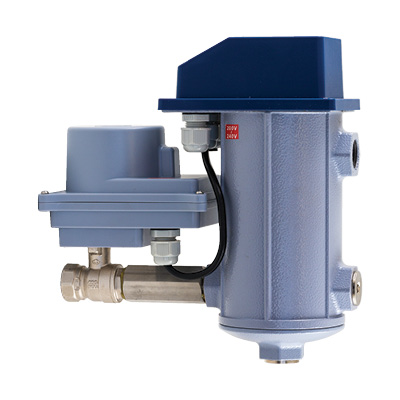

The absorption filter features a high quality industrial float drain with ball valve for easy condensate removal, and a threaded connection is used as both an inlet and outlet.

The filter housing is marked with direction of air flow for ease of use, and the auto drain is serviceable without shutting off the air supply.

| CODE | DESCRIPTION | MICRONS | FLOW RATE CFM | MAX PRESSURE PSI | MAX TEMP | CONNECTION SIZE |

| IN-F15A-150 | Absorption Filters 1/2″ | 0.01 | 35 | 232 | 65°C | 1/2” |

| IN-F20A-150 | Absorption Filters 3/4″ | 0.01 | 70 | 232 | 65°C | 3/4” |

| IN-F25A-150 | Absorption Filters 1″ | 0.01 | 105 | 232 | 65°C | 1” |

| IN-F40A-150 | Absorption Filters 1 1/2″ | 0.01 | 210 | 232 | 65°C | 1 1/2” |

| IN-F50A-150 | Absorption Filters 2” | 0.01 | 630 | 232 | 65°C | 2” |

| IN-F63A-150 | Absorption Filters 2 1/2” | 0.01 | 840 | 232 | 65°C | 2 1/2” |

The main function of the absorption filter is to absorb smells, odors and taste from compressed air, making it suitable and comfortable for breathing.

This degree of filtration also offers other benefits including virtually oil free air, making it extremely appropriate for applications such as high quality painting, glass manufacturing and laser cutting, when used with the correct air drying process.

For breathing air, the absorption filter must be used in conjunction with other specified equipment, including the Infinity pre-filter, coalescing filter and dryers. This will ensure that air is at the correct quality and highest of standards.

It is also recommended that all breathing air systems are regularly tested.

To select the correct size of filter for a particular application, choose on the basis of air flow and system pressure, rather than pipe size. Select a filter large enough to ensure that the air exits the filter at a low velocity.

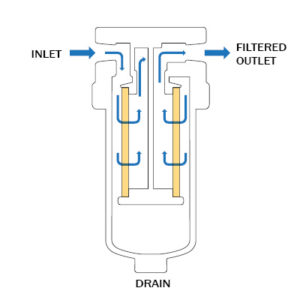

The diagram below shows the absorption filtration process.

As air enters the housing, it flows through the filter element from outside to in, during which the activated carbon in the element absorbs smells and odours from the compressed air. The air then exits the housing through the outlet port.

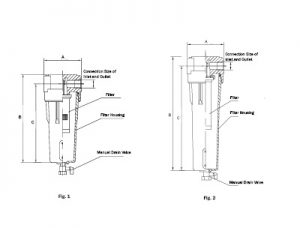

| CODE | FIG | A | B | C | CONNECTION SIZE |

| IN-F15A-150 | 1 | 104 +/-0.8 | 243 +/-1.2 | 217 +/-1.2 | 1/2” |

| IN-F20A-150 | 1 | 104 +/-0.8 | 313 +/-1.2 | 287 +/-1.2 | 3/4” |

| IN-F25A-150 | 1 | 104 +/-0.8 | 313 +/-1.2 | 287 +/-1.2 | 1” |

| IN-F40A-150 | 2 | 138 +/-0.8 | 624 +/-1.2 | 624 +/-1.2 | 1 1/2” |

| IN-F50A-150 | 2 | 148 +/-0.8 | 685 +/-1.2 | 639 +/-1.2 | 2” |

| IN-F63A-150 | 2 | 150 +/-0.8 | 850 +/-1.2 | 800 +/-1.2 | 2 1/2” |

Related Literature