Laminar flow is an integral component of compressed air efficiency. Believe it or not, laminar flow is controlled solely by the airline used in a compressed air system. To fully understand the effects of laminar flow in a compressed air system, we need to explain exactly what it is.

Fluids & gases are unique in their ability to travel. Unlike solid molecules that remain stationary whose molecules tend to join others of the same kind, fluid molecules aren’t so picky. Fluid molecules, such as gases and liquids, partner with different molecules and are difficult to stop.

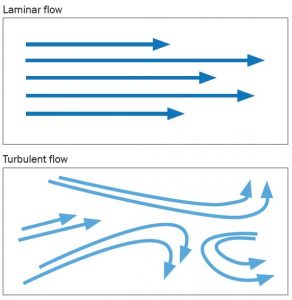

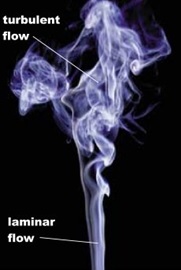

Laminar flow describes the ease with which these fluids travel; good laminar flow describes fluid travelling as straight as possible. On the contrary, when fluid is not travelling straight, the result is turbulence, or a reduction in laminar flow. This is depicted well in the cigarette image below; as the smoke comes off the cigarette, this would be considered perfect laminar flow. As it travels away, the molecules display imperfect turbulent flow.

Turbulent air flow essentially results in an inefficient compressed air system. This may not seem like a major concern; however, it has huge impacts on compressor efficiency. Fluid molecules bounce and circle within their path, causing huge energy wastage. In compressed air systems, this turbulent airflow results in pressure drop. How do you avoid this from happening? It all comes down to compressed air system design.

The design and material of the air pipe, as well as the positioning of elbows and joints, has a direct correlation to laminar flow and pressure drop. To avoid high energy consumption of your compressed air system, reducing pressure drop is key.

If your system is experiencing high pressure drop, your compressor has to work overtime to provide the required air pressure. When your compressor works overtime, it not only increases your maintenance costs, but also your energy bills.

Laminar flow works in conjunction with the “boundary layer”; this is the very first layer of compressed air that touches the wall of the pipe. Through the use of Infinity fittings, such as the Infinity Reducing tee, the air can travel down the dropper with ease, creating a smooth transition without disruption to the laminar flow.

If you would like more information on laminar flow and our compressed air solutions, OR help designing your compressed air system contact the Infinity Pipe Systems Project Management team on 1300 272 982 or at info@infinitypipesystems.com.au.