…and how to avoid them

Compressed air performance is often blamed on the compressor, when the real issue sits downstream in the pipework. Incorrect pipe sizing is one of the most common and costly mistakes in compressed air system design, leading to pressure loss, inefficiency, and avoidable operating expense.

Understanding where pipe sizing goes wrong is the first step toward designing a system that delivers consistent pressure, reliable flow, and long-term efficiency.

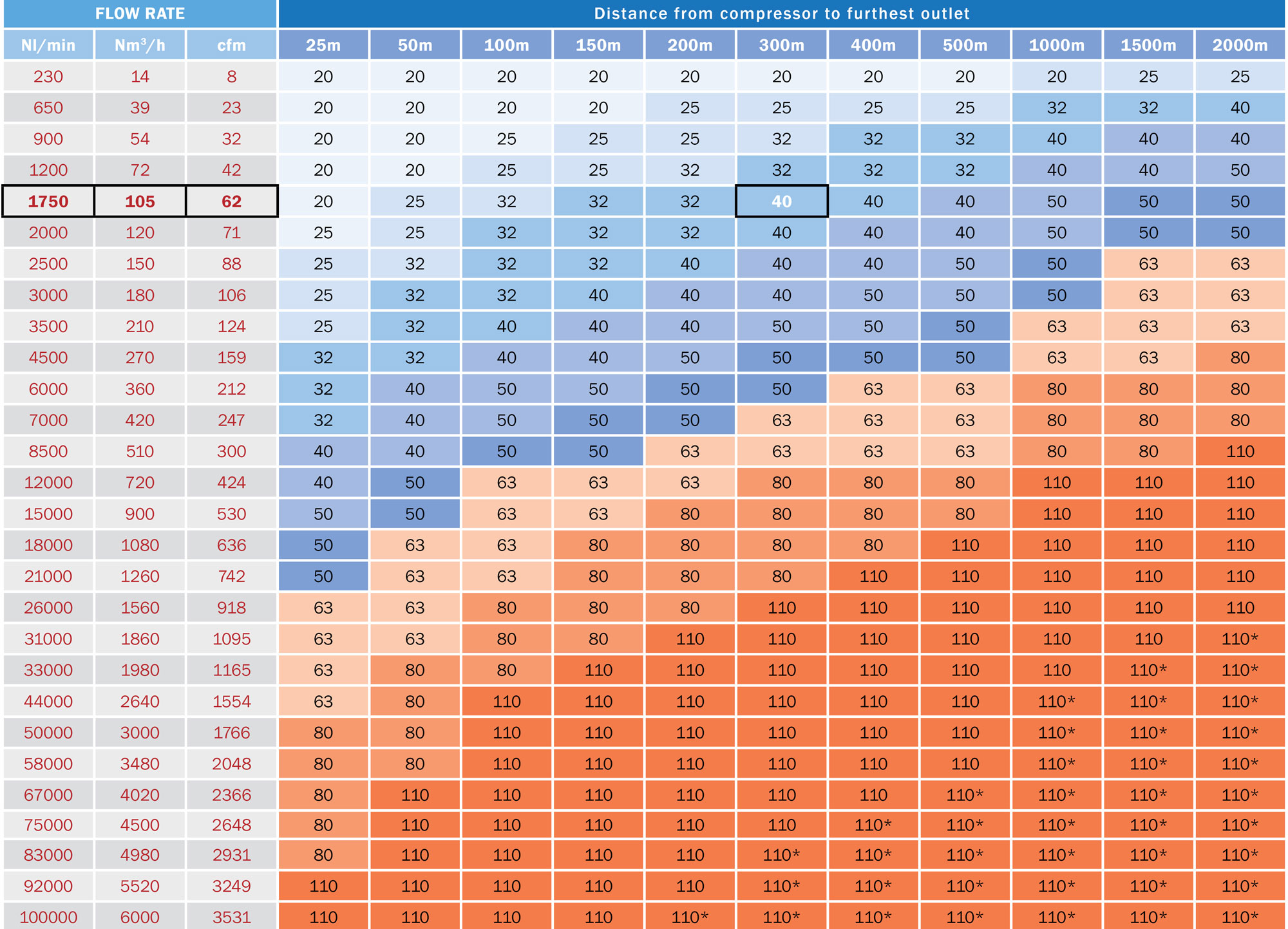

Correct pipe sizing starts with understanding airflow demand and distance. Our Compressed Air Pipe Sizing Chart provides a practical reference for selecting mainline diameter.

1. Undersizing the Main Line

Undersized pipework restricts airflow, increasing velocity and friction losses. The result is pressure drop at the point of use, even when the compressor appears adequately sized.

Common symptoms:

- Tools underperform during peak demand

- Pressure fluctuations across the facility

- Operators compensating by increasing compressor pressure

Better approach:

Size the main line based on total flow demand and distance from the compressor, not just connection size or legacy pipework.

Read our guide: Design Considerations for Compressed Air Piping Systems

2. Sizing Based on Compressor Outlet Only

A frequent mistake is selecting pipe diameter based solely on the compressor outlet size. This ignores system length, fittings, and cumulative demand across multiple drops.

Compressed air systems behave dynamically. The pipe network must support peak flow conditions, not just nominal compressor output.

Better approach:

Use a pipe sizing reference that factors in airflow (L/s or CFM) and system length, ensuring pressure stability throughout the network.

3. Ignoring Future Expansion

Designing pipework only for today’s demand limits flexibility and often forces premature upgrades. Adding machines later can quickly push an undersized system beyond its operating envelope.

Common outcome:

What started as a “cost-saving” decision becomes a retrofit problem.

Better approach:

Allow headroom in mainline sizing to accommodate future equipment, additional drops, or production growth with minimal disruption.

4. Overcompensating with Higher Pressure

When pressure drop appears, a common response is to increase compressor set pressure. This masks the symptom but increases energy consumption and accelerates wear on equipment.

Raising pressure is one of the least efficient ways to solve a flow problem.

Better approach:

Address the root cause by correcting pipe diameter and layout. Proper sizing reduces pressure drop without increasing energy demand.

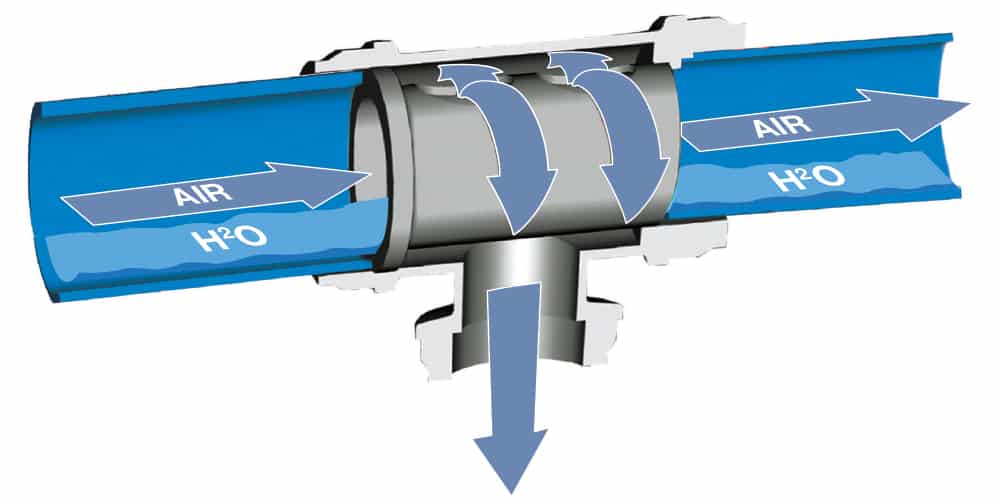

5. Overlooking the Impact of Fittings and Layout

Elbows, tees, valves, and long runs all contribute to pressure loss. Tight layouts and excessive fittings can undermine even correctly sized pipework.

Better approach:

Design with smooth flow paths, gradual direction changes, and high-quality fittings. Pipe sizing should be considered alongside system layout, not in isolation.

6. Treating Pipe Sizing as a One-Time Decision

Compressed air systems evolve over time. What worked five years ago may no longer support current production requirements.

Better approach:

Review pipe sizing whenever demand changes, equipment is added, or pressure issues emerge. Pipework should be part of ongoing system optimisation, not a set-and-forget asset.

Many of these sizing mistakes only become visible once a system is under load. If pressure instability is already occurring, our Pressure Drop Troubleshooting Guide provides a step-by-step diagnostic process.

Use the Right Reference

Pipe sizing doesn’t need to be complex, but it does need to be deliberate. A clear sizing reference helps eliminate guesswork and supports better design decisions early in the process.

Infinity Pipe Systems provides a practical compressed air pipe sizing chart that helps determine the appropriate mainline diameter based on airflow and distance from the compressor.

Final Takeaway

Pipe sizing errors are rarely obvious at installation, but they show up quickly in energy costs, performance issues, and operational frustration.

Getting pipe sizing right from the start, and revisiting it as systems evolve, is one of the simplest ways to improve compressed air efficiency and reliability.