Compressed air systems rarely fail overnight. More often, performance degrades gradually as facilities grow, equipment is added, and systems are modified to keep up with demand.

Knowing whether your system needs a targeted upgrade – or a broader redesign – can prevent unnecessary capital spend while restoring performance and reliability.

Signs a System May Be Reaching Its Limit

Over time, many established sites develop similar patterns:

- Additional compressors added to maintain pressure.

- New equipment tied into existing lines.

- Pressure loss at the far end of the system.

- Rising energy consumption.

- Patchwork modifications from previous upgrades.

- Inconsistent air delivery across production areas.

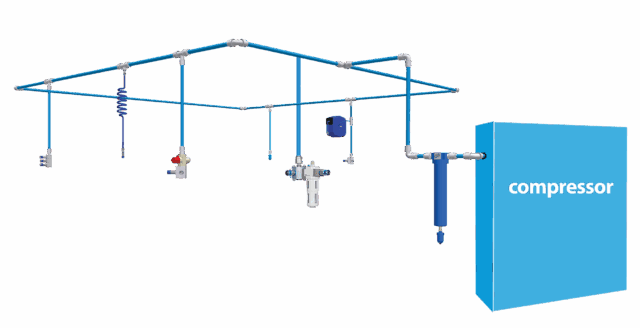

These symptoms usually point to distribution constraints, not a lack of air generation.

Read our guide: Pressure Drop Troubleshooting in Compressed Air Systems.

When an Upgrade Is Often Enough

Targeted upgrades can be effective where:

- Core pipe sizing is still appropriate.

- The original layout supports efficient airflow.

- Issues are isolated to specific areas.

- Bottlenecks can be removed without re-engineering the full network.

In these cases, strengthening parts of the system can restore performance without major disruption.

Correct pipe sizing starts with understanding airflow demand and distance. Our Compressed Air Pipe Sizing Chart provides a practical reference for selecting mainline diameter.

When Replacement or Redesign Is the Smarter Call

A full redesign is usually required where:

- Production has expanded well beyond the original design brief.

- Compressors have been added to compensate for pressure loss.

- Air stability affects output, quality or uptime.

- Previous modifications have created flow restrictions.

Adding more compressors rarely fixes a distribution problem. In many cases, the issue sits in how air is delivered, not how much air is produced.

Read our guide: Design Considerations for Compressed Air Piping Systems.

Final Takeaway

Understanding whether performance limits are caused by air generation or air distribution is the first step toward making the right investment decision.

In many cases, improving the delivery of air has a greater impact than increasing supply – and avoids locking in inefficiencies for your projects next phase of growth.