- Home

- Shop

- Compressed Air Filtration

- Industrial Filtration

- Industrial Pre-Filter

Industrial Pre-Filter

Industrial Pre-Filter

Code Number – IN-F-320

- Removes solid particles such as dust, pollen, mould and bacteria from the air

- Filtration rating: 5µm

- Oil content: 5ppm

- Maximum pressure: 232 psi

- Description

- Technical

- Related Literature

- Contact Form

Product Description

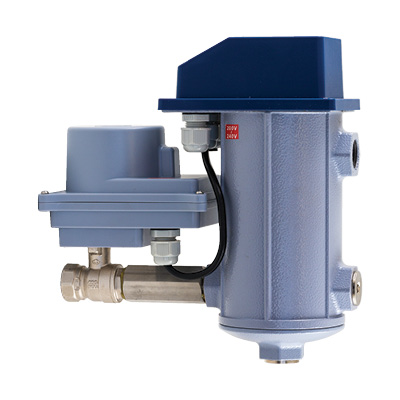

The Infinity industrial pre-filter is made of high quality aluminium alloy and carbon steel.

Featuring a compact design to reduce space for maintenance, its surface is coated with epoxy resin powders so as to improve its durability and resistance to corrosion.

The pre-filter features a high quality industrial float drain with ball valve for easy condensate removal and a threaded connection is used as both an inlet and outlet.

The filter housing is marked with direction of air flow for ease of use, and the auto drain is serviceable without shutting off the air supply.

| CODE | DESCRIPTION | MICRONS | FLOW RATE CFM | MAX PRESSURE PSI | MAX TEMP | CONNECTION SIZE |

| IN-F15P-320 | Industrial Pre-Filters 1/2″ | 5 | 35 | 232 | 65°C | 1/2” |

| IN-F20P-320 | Industrial Pre-Filters 3/4″ | 5 | 70 | 232 | 65°C | 3/4” |

| IN-F25P-320 | Industrial Pre-Filters 1″ | 5 | 105 | 232 | 65°C | 1” |

| IN-F40P-320 | Industrial Pre-Filters 1 1/2″ | 5 | 210 | 232 | 65°C | 1 1/2” |

| IN-F50P-320 | Industrial Pre-Filters 2” | 5 | 630 | 232 | 65°C | 2” |

| IN-F63P-320 | Industrial Pre-Filters 2 1/2” | 5 | 840 | 232 | 65°C | 2 1/2” |

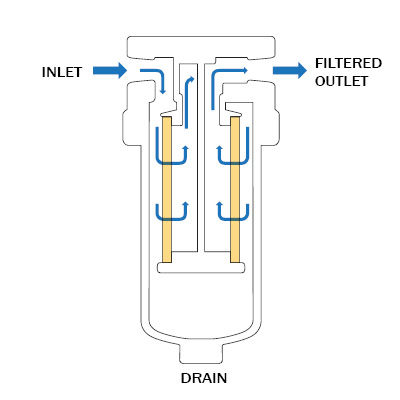

The function of a pre-filter (or particulate filter) is to remove solid particles such as dust, pollen, mould and bacteria from the air.

Particles are removed from the air using a two port filter housing and pre-filter element, specifically designed for this purpose. The ultra-fine fibres of the pre-filter element capture microscopic particles up to 50 times smaller than the eye can see through a combination of diffusion, interception and inertial impaction.

With smaller particles, diffusion occurs when the random motion of the particles causes them to collide with fibres. Interception occurs when larger particles directly collide with a fibre. When a particle’s inertia leads to its collision with a fibre, this is known as inertial impaction.

To select the correct size of filter for a particular application, choose on the basis of air flow and system pressure, rather than pipe size. Select a filter large enough to ensure that the air exits the filter at a low velocity.

Pre-filters are ideal for general purpose air tools and building sites, and used as the first stage before an Infinity coalescing and absorption filter. It is also recommended that they be used to filter the air before it reaches the air dryer.

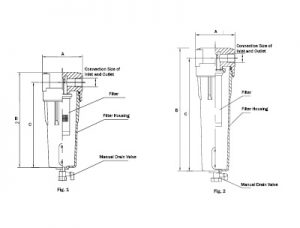

The diagram above shows the pre-filter process.

Compressed air flows from the compressor, entering the filter housing via the inlet. As the air flows through the filter element from inside to out, dust particles and condensate are removed and collected at the bottom of the bowl where they are ejected automatically by the auto drain system.

| CODE | FIG | A | B | C | CONNECTION SIZE |

| IN-F15P-320 | 1 | 104 +/-0.8 | 243 +/-1.2 | 217 +/-1.2 | 1/2” |

| IN-F20P-320 | 1 | 104 +/-0.8 | 313 +/-1.2 | 287 +/-1.2 | 3/4” |

| IN-F25P-320 | 1 | 104 +/-0.8 | 313 +/-1.2 | 287 +/-1.2 | 1” |

| IN-F40P-320 | 2 | 138 +/-0.8 | 624 +/-1.2 | 624 +/-1.2 | 1 1/2” |

| IN-F50P-320 | 2 | 148 +/-0.8 | 685 +/-1.2 | 639 +/-1.2 | 2” |

| IN-F63P-320 | 2 | 150 +/-0.8 | 850 +/-1.2 | 800 +/-1.2 | 2 1/2” |

Related Literature