When Air Turns Dangerous: Understanding and Preventing Hose Whip

Providing a safe working environment is essential, especially when using pneumatic tools and compressed air.

Providing a safe working environment is essential, especially when using pneumatic tools and compressed air.

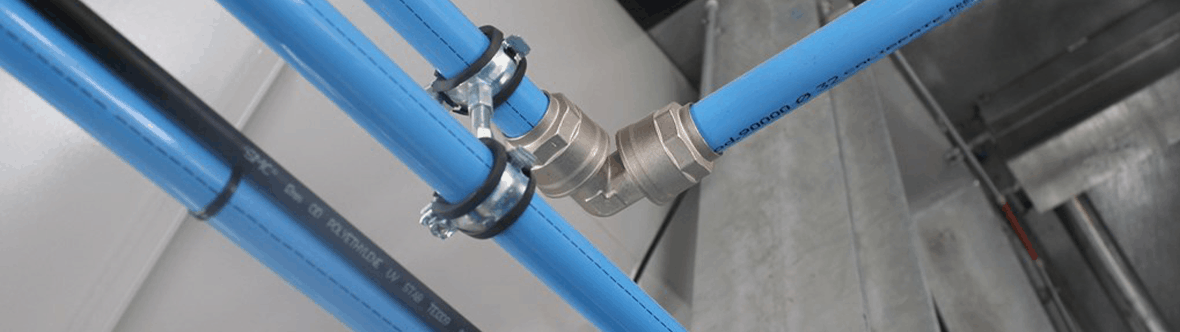

Infinity Pipe Systems explains the difference between Infinity Push Fit system vs Press Fit system

While the two most popular grades of stainless steel might seem identical at a glance, they hold important differences that can lead to substantial savings over the life of your project depending on your intended uses.

The main function of pneumatic tubing and hose is to deliver compressed air to actuators, valves, and other air tools.

Leaks can be found in most industrial systems, and some leak more than others.

No one knows when the Coronavirus pandemic will officially end, but it is clear how important a compressed air system is to businesses. Nothing happens without compressed air.

Its is important to know how cold ambient temperatures affect your compressed air system.

Did you know aluminium piping was initially introduced in the late 1980’s as a smarter alternative to plastic and steel pipe in compressed air systems?

Infinity Pipe Systems has compiled a list of handy hints and important safety precautions to consider when working with compressed air lines.