When it comes to compressed air efficiency, laminar flow is everything. The smoother your air moves through the system, the less energy is wasted. And believe it or not, laminar flow is influenced almost entirely by the air line you use.

What Is Laminar Flow?

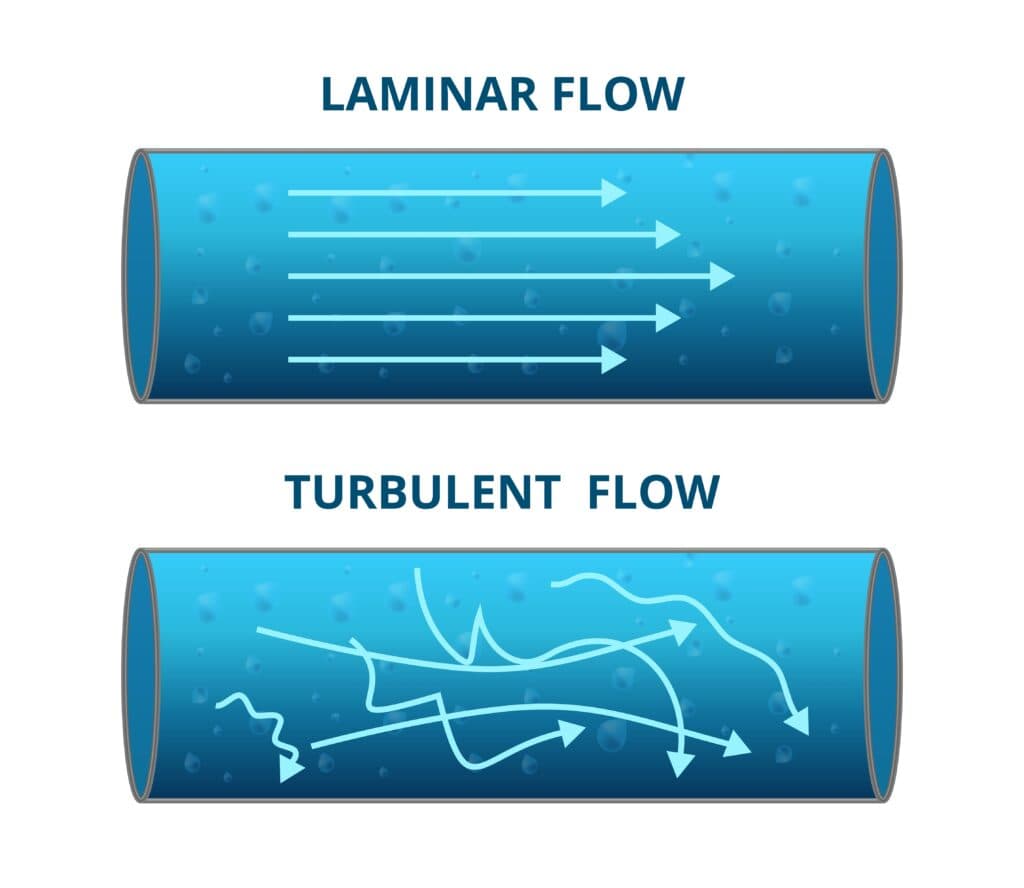

In fluid dynamics, laminar flow describes how smoothly a gas or liquid moves through a pipe or channel. When air flows in straight, parallel layers with minimal disturbance, that’s laminar flow. When it becomes chaotic or uneven, we call it turbulent flow.

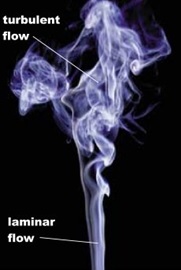

A simple way to visualise this is smoke rising from a candle or cigarette. At first, it moves in a clean, straight line (laminar), but as it drifts away, it begins to swirl and break apart (turbulent).

Why Laminar Flow Matters

In a compressed air system, turbulent airflow equals inefficiency. As air molecules swirl and collide within the pipe, they create resistance known as pressure drop. The more turbulence, the greater the pressure loss.

When pressure drops, your compressor has to work harder to maintain required output. That means increased energy consumption, higher operating costs, and more wear on your equipment. Over time, this can dramatically affect both performance and reliability.

Designing for Efficiency

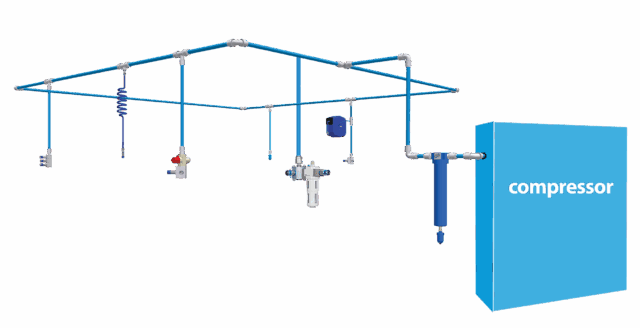

Laminar flow is about the entire system design, not just the compressor. The material and internal surface of the airline, along with the number and placement of fittings, elbows, and joints, all directly affect how smoothly air can move through the network.

That’s why Infinity aluminium and stainless steel piping systems are engineered with:

- Smooth internal bores that minimise turbulence

- Precision-machined fittings that maintain flow path integrity

- Optimised joint designs that reduce boundary layer* disruption

*The boundary layer is the thin layer of air that moves along the inner pipe wall. Smooth internal surfaces and high-quality fittings help maintain this layer, allowing air to flow freely without friction or energy loss.

Read our guide: Design Considerations for Compressed Air Piping Systems

The Result

When airflow remains smooth and uninterrupted, every part of your compressed air system performs more efficiently.

Reduced pressure drop

Less resistance means better flow. Laminar airflow travels evenly through the pipe network, maintaining consistent pressure from the compressor to the point of use. This reduces the loss of air power caused by turbulence and friction, helping equipment operate at optimal performance.

Lower energy use

When air moves efficiently, your compressor doesn’t have to work as hard to maintain the required pressure. Lower running hours and reduced load cycles translate directly into lower electricity bills and a smaller carbon footprint.

Less wear and maintenance

Stable, balanced airflow reduces stress on your entire system - from the compressor to tools and downstream equipment. With less vibration and pressure fluctuation, mechanical components last longer, service intervals are extended, and unscheduled downtime is minimised.

Consistent air quality

Smooth, uninterrupted flow helps maintain uniform pressure and clean, dry air across every outlet. This ensures tools and production processes receive a steady supply of high-quality compressed air, reducing the risk of defects, contamination, or inconsistent performance.

Talk to the Infinity Experts