One of the most common questions we get asked about aluminium compressed air piping is what size air pipe is needed for our client’s system. Unfortunately, this isn’t a one size fits all industry. Some people have greater compressed air requirements than others and if you choose a pipe that is undersized, your system’s performance can suffer. To make things simple for you, you can use our compressed air pipe sizing chart to quickly determine the ideal size. Here’s how it works.

Know your air flow

The first thing you need to know to use the compressed air pipe sizing chart is the maximum amount of air your compressor can produce. This is simple to figure out. It should be in the compressor’s manual but if you don’t have that you can always look it up online. The max output can be measured in litres per second, m3 per minute/hour, or cubic feet per minute (cfpm).

Determine the furthest outlet

The other thing you need to know is the distance of your compressor to the further most point in your pipe system. Make sure to measure along the pipeline, not the space between the two points, factoring in how bends and couplings contribute to the distance.

Using the compressed air pipe sizing chart

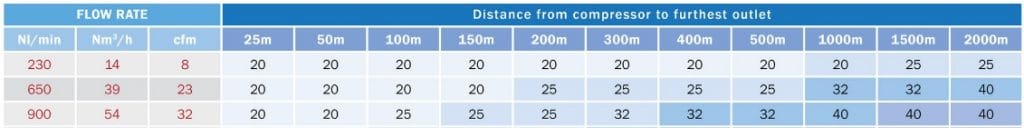

Now that you have the flow rate and the distance of the furthest point in your air pipe system (including bends) from the compressor, you are able to determine the ideal air pipe sizing for your system by using our air pipe size chart.

First, choose the flow rate of your compressor from the left-hand columns. Next, choose the distance between your compressor and the further most using point in your system. If you cross the lines of flow rate and distance, you will have the recommended pipe size diameter in millimetres.

Planning for the future

An important factor that our air pipe size chart can’t account for is the amount of air flow you may require in the future. For example, if you upgrade to a more powerful compressor but keep the existing pipe, you’re likely to suffer from pressure drops as the air struggles to travel from one end of the pipe to the other. To counter pressure drops, you can set your compressor to a higher setpoint but this requires more energy which results in greater running costs.

Planning ahead will ensure your air pipe is capable of handling the air flow produced which in turn will reduce any excessive running costs. Our project management team are able to assist you with planning the design or upgrade of your compressed air piping system.