When Air Turns Dangerous: Understanding and Preventing Hose Whip

Providing a safe working environment is essential, especially when using pneumatic tools and compressed air.

Clear, practical guidance for compressed piping systems.

Whether you’re running a workshop, fitting out a new production line, or troubleshooting pressure issues, this library gives you practical, no-nonsense guidance you can actually use.

From pipe sizing to fittings, system design, safety, and industry-specific advice – this guide has everything you need to build a safer, smarter, more efficient network.

Designing an efficient compressed air piping system requires balancing flow performance, pressure stability, material selection, and long-term maintainability. This guide outlines seven key design considerations based on best practice principles and engineering standards.

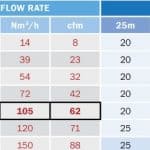

Infinity Pipe Systems Aluminium Compressed Air Pipe Sizing Chart allows you to determine the diameter (mm) of the compressed air pipe main line.

When it comes to compressed air efficiency, laminar flow is everything. The smoother your air moves through the system, the less energy is wasted. And believe it or not, laminar flow is influenced almost entirely by the air line you use.

Providing a safe working environment is essential, especially when using pneumatic tools and compressed air.

Infinity Pipe Systems explains the difference between Infinity Push Fit system vs Press Fit system

The PA LAL Holdings Warehouse in Fiji, along with nine buses, was destroyed by fire. A fire-resistant compressed air system was provided by Infinity Pipe Systems as part of the rebuild

12 months ago, Pneumatics Direct completed an installation at the Tasty Fresh workshop in the Gold Coast

Quaker Oats Australia Pty Ltd is Australia’s leading manufacturer and supplier of quality oat products for human consumption in 25 kg process formed bags and bulk in container.

Infinity Supply, Design, Project Manage Case Study with D’sorgna Melbourne in 2018.

Speak with our team for clear, practical guidance, and solutions that keep up when your needs change.