Choosing the Right Filters for Your Compressed Air System

One of the greatest lessons you could learn when it comes to compressed air distribution is to never underestimate the damage that can be caused by condensation and contamination

One of the greatest lessons you could learn when it comes to compressed air distribution is to never underestimate the damage that can be caused by condensation and contamination

Quaker Oats Australia Pty Ltd is Australia’s leading manufacturer and supplier of quality oat products for human consumption in 25 kg process formed bags and bulk in container.

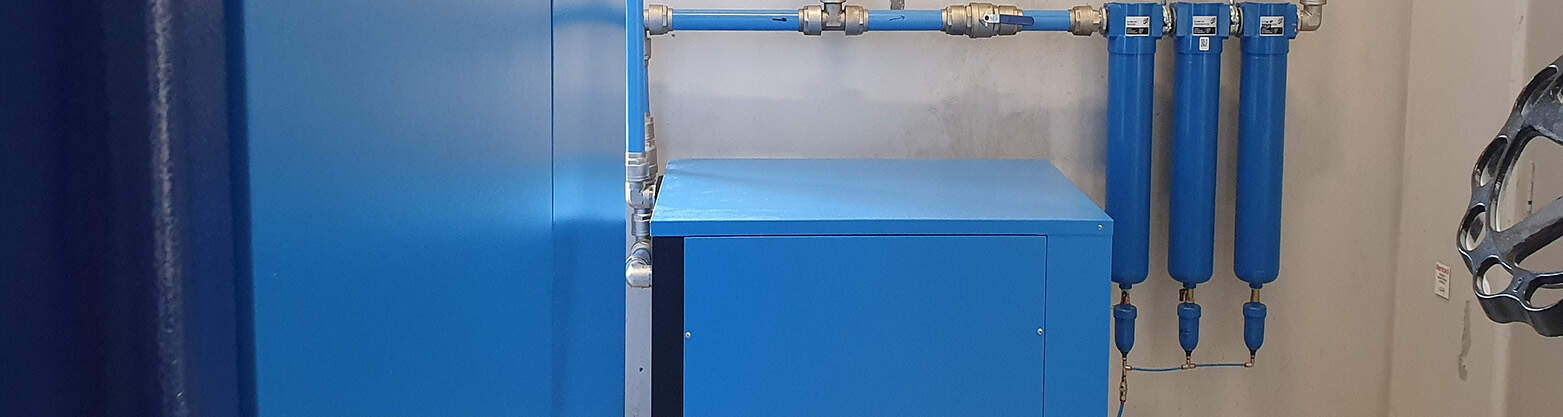

By removing contaminants, compressed air filter systems protect the equipment and can actually extend the life of an air compressor system.

Having an efficient and working air line is crucial to managing a successful and effective workshop.

Infinity Supply, Design, Project Manage Case Study with D’sorgna Melbourne in 2018.

Connecting air hose fittings is an straight forward task and they are designed to be easy to install.

The new Infinity air hose fittings have been designed specifically for the Australian compressed air industry. With an internal locking system and easy one touch connection these couplings provide safe and efficient one hand connection and operation.

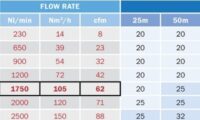

One of the most common questions we get asked about aluminium compressed air piping is what size air pipe is needed for our client’s system. Unfortunately, this isn’t a one size fits all industry. Some people have greater compressed air requirements than others and if you choose a pipe that is undersized, your system’s performance can […]

In a compressed air piping system, a reducing tee allows you to join the same size air pipe with an intersecting smaller pipe to form a T junction. Reducing tees are used to redirect the pipeline to a dropper which may be connected to a piece of equipment such as an air hose reel.

Infinity High Flow fittings are available in 63mm, 80mm and 110mm and NEW 168mm sizes.